What is TransBuild

Beam & Block Slab

Precast Wall Panels

Beam & Block Slab?

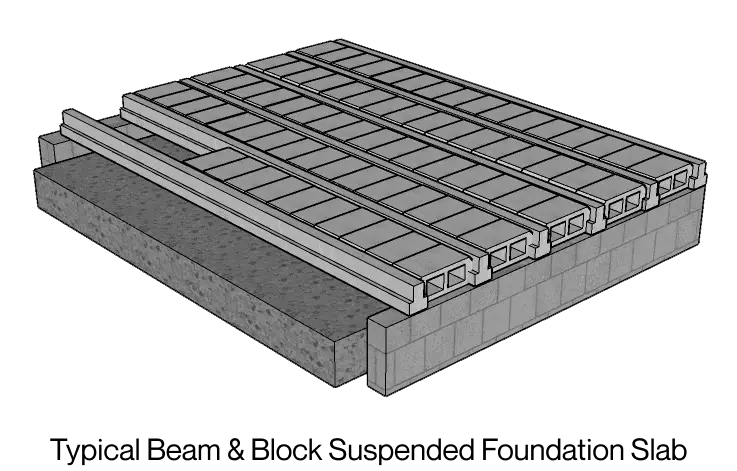

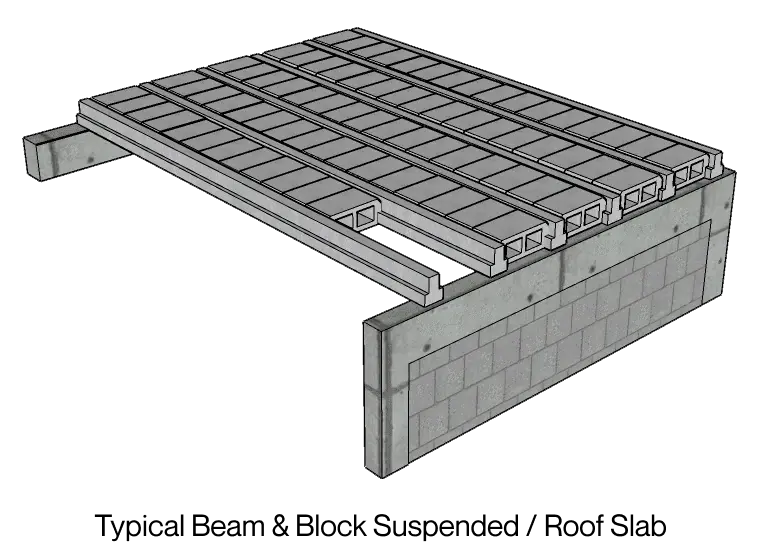

Modern construction primarily uses two types of concrete floor systems: ground-bearing and suspended. In Kerala, ground-bearing poured concrete slabs have been the traditional choice. However, Beam & Block, a type of suspended floor system widely used in advanced markets, is gaining traction.

Suspended floors do not depend on the ground for support. Instead, they rely on the external walls and the underlying foundations, making them a robust and adaptable choice for various construction environments.

The beam and block floor system is gaining popularity for both domestic and commercial projects due to its cost-efficiency, quick assembly, and minimal need for specialized labor or equipment. Off-site manufacturing speeds up installation and reduces weather-related delays. This flooring option offers excellent noise reduction, fire resistance, and compatibility with underfloor heating, making it a reliable and versatile solution for modern construction.

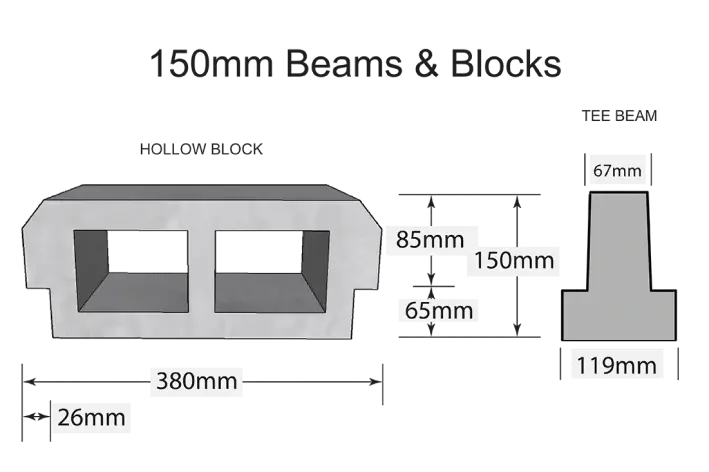

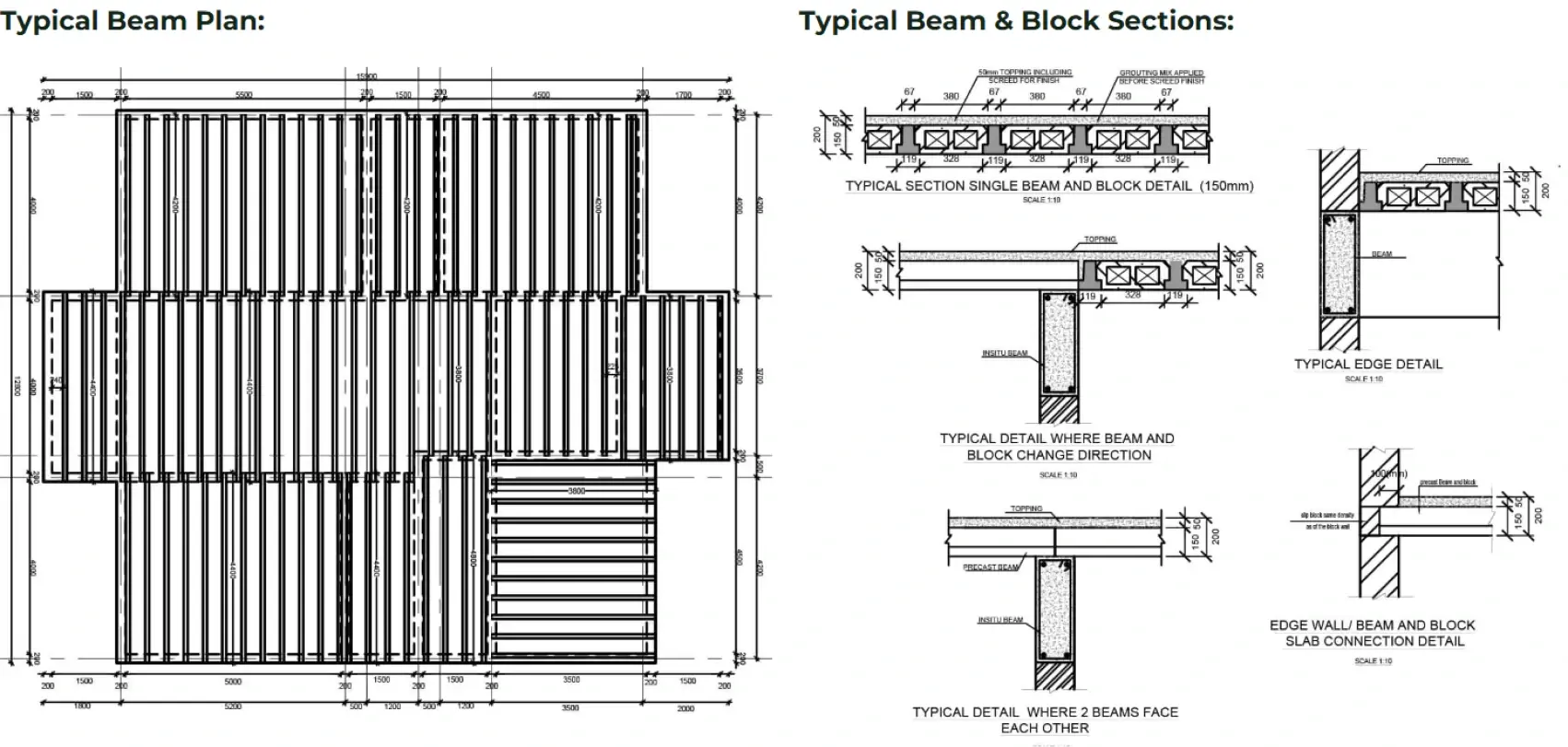

Precast concrete inverted T-beams are supported by perimeter and internal load-bearing walls. These beams, available in 150mm or 225mm depths and up to 6m in length, are designed based on span and load requirements. Lightweight concrete infill blocks are placed between the beams, followed by a sand-cement grout. This grout fills gaps, ensuring even load distribution, preventing movement, and enhancing air tightness by keeping out insects and vermin. This design provides durability, stability, and efficiency for various construction needs.

Technical Specs

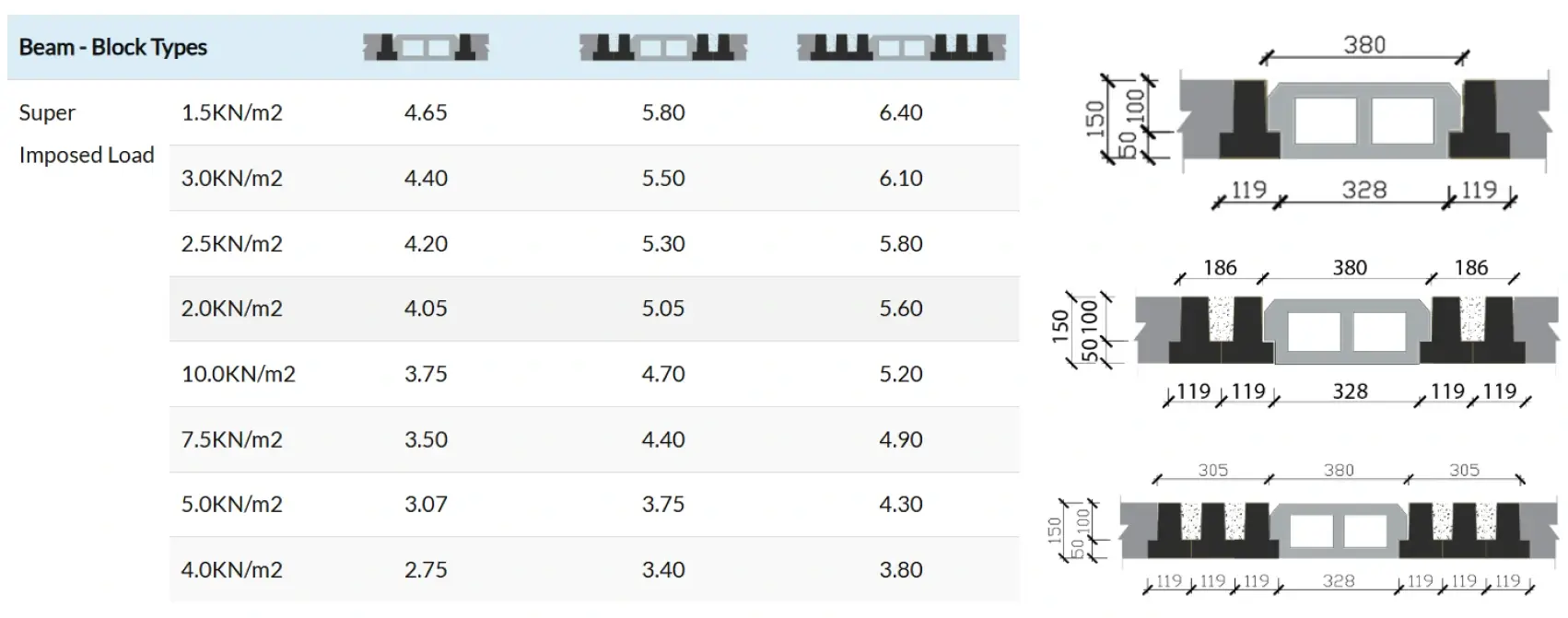

Technical BrochureLoad & Span Tables

150mm Load TableDensity of Hollow Infill blocks = 1160Kg/m³, Topping (50mm)= 1.25KN/m2,

Celling plaster for suspended floor 12mm thick + tiles 18mm = 0.72KN/m2

Residential houses = 1.5KN/m2, Hotels = 2.0KN/m2, Classrooms = 3.0KN/m2,

Shops = 4.0KN/m2, Workshops = 5.0KN/m2; Industrial walkways = 7.5KN/m2

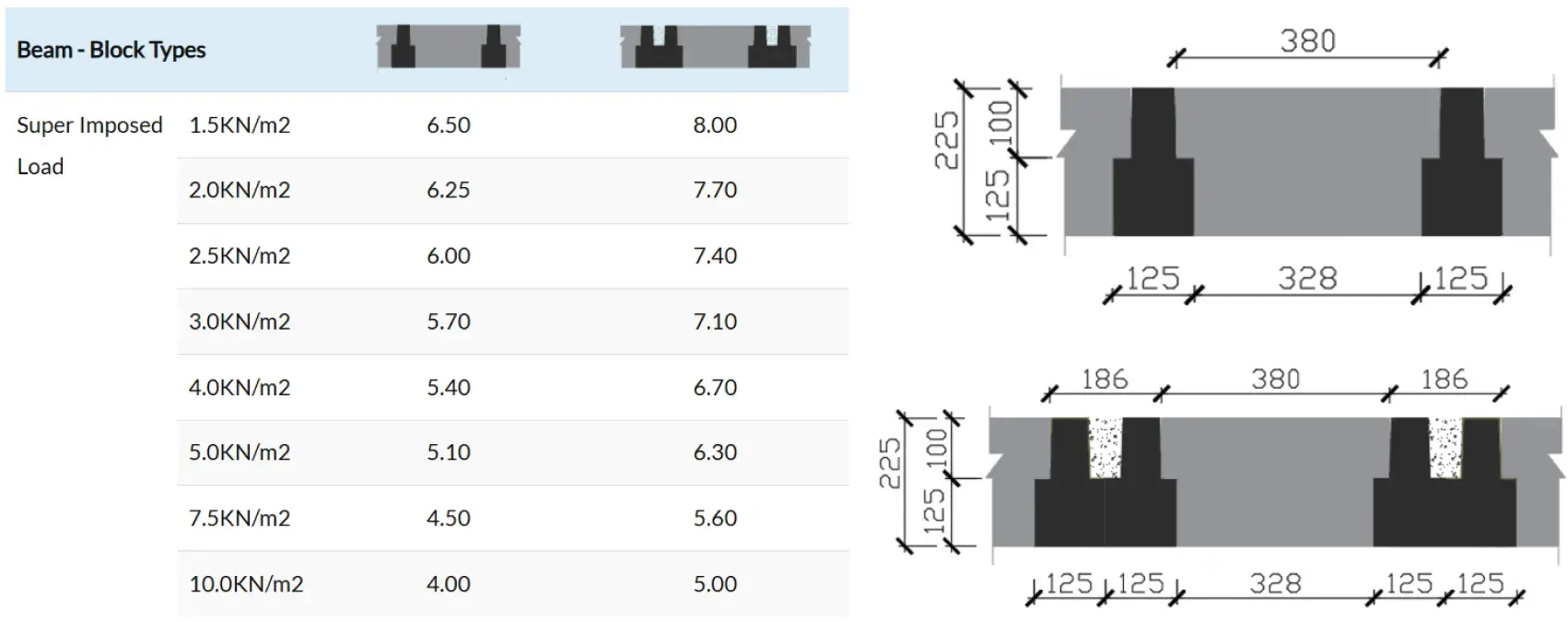

225mm Load Table

Density of Hollow Infill blocks = 1160Kg/m³, Topping (50mm)= 1.25KN/m2,

Celling plaster for suspended floor 12mm thick + tiles 18mm = 0.72KN/m2

Residential houses = 1.5KN/m2, Hotels = 2.0KN/m2, Classrooms = 3.0KN/m2,

Shops = 4.0KN/m2, Workshops = 5.0KN/m2; Industrial walkways = 7.5KN/m2

Our Commitment to Quality

TransBuild maintains the highest standards for Beam and Block products through strict quality control. Sustainable raw materials are carefully selected and monitored throughout production, from casting beams to creating blocks.

Advanced testing ensures structural integrity, durability, and load-bearing capacity, including checks for compressive strength and dimensional accuracy. Quality control extends to curing and finishing, guaranteeing that every product meets or exceeds industry safety and performance standards.